For most of us, the notion that molasses would flood a city causing fatalities and destruction on its face seems implausible. Yet it happened in Boston in 1919.

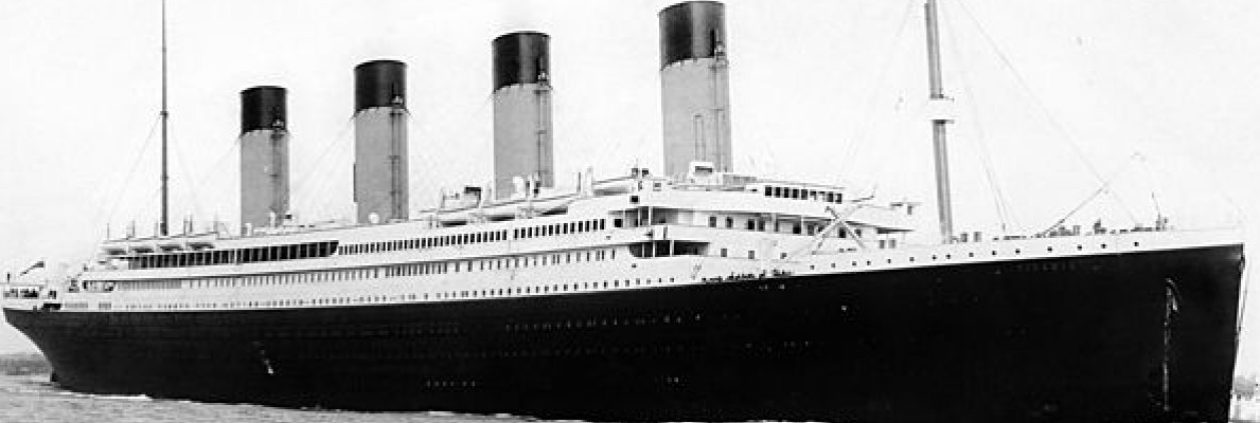

Public Domain (via Wikipedia)

Industrial alcohol (used for machinery and other industrial applications) was very profitable and used for the war effort. It was made from fermented molasses so large tanks were constructed to hold it. A giant tank for it was built in 1915 along Boston’s waterfront on Commercial Street. Operated by the Purity Distribution Company (a subsidiary of United States Industrial Alcohol). The tank was immense measuring 50 feet high, 90 feet in diameter and could hold up to 2.5 million gallons. Back then, the usual standard was to use rivets (welding had not been invented yet) when connecting sections of metal together. Because of the fumes caused by fermentation and the pressure created, it posed a risk. There were leaks and occasional rumbles, but a vent was in place and open during the spring, summer, and fall. However, they were sealed during the winter since temperatures were usually very cool.

Shipments for molasses came in from ships in the harbor and transferred to the tank. Then later it would be transferred to an ethanol plant via pipeline in Cambridge. A recent delivery of molasses had nearly filled the tank. But for Purity, there was another issue. With the war over and Prohibition coming, the demand for industrial alcohol was going to be severely limited (there were still uses from industrial to baking but lower demand meant lower revenues for the company).

Public Domain (via wikipedia)

January 15, 1920 was an unseasonably warm day with temperatures soaring up to 40 degrees Fahrenheit and higher possibly by noon that day. With the vents closed, the fumes had nowhere to go and pressure built up inside the tank. At 12:30 pm people heard sounds that sounded like machine guns firing. It was likely the rivets being popped out by the pressure inside the tank. And then the tank exploded sending the nearly 2.5 million tons of molasses into Boston. The wave was estimated to be 15-40 feet and about 160 feet wide. Traveling at about 35 miles per hour, it destroyed several city blocks, leveled buildings, damaged autos and killed 21 people with 150 injured. Since molasses is very thick, it made for difficult breathing if it got into your nostrils or mouths. Many died from asphyxiation or drowned. Horses were knocked down and died on the spot with so many that many compared them to being sticky fly paper.

Source: U.S. Library of Congress,Digital ID: (digital file from original) anrc 1496

Clean-up efforts started immediately but lasted for quite a while. Molasses went everywhere and no matter where you went in Boston, you were likely to encounter the sticky stuff in some form. It was on subway platforms, inside streetcars, pay telephones, even inside public buildings. Pedestrians tracked the molasses everywhere they went spreading further. Cleanup crews were kept busy cleaning it all up using salt water. And from many accounts, it appears the city would smell like molasses for some years to come.

Aftermath

Fingers were pointed at the company, who tried initially to claim it was sabotage. An investigation into how it was built, and approvals were done showed a lot of corners were cut in its design and construction. Lawsuits were filed and consolidated into one of the first-class action suits ever to be done. Stories of known leaks where kids filled buckets with the leaking molasses did not help the company either. Ultimately the company paid out to victim’s families around $628,000.

The disaster highlighted the need for more rigorous standards for construction, required safety tests for tanks containing liquids, and ongoing safety checks. It was determined the company ignored basic safety tests when constructing and ignored the groaning sounds when tank was filled. Also the company used thinner steel than was commonly used for tanks in that day. They also covered up the leaks by painting the tank brown. Later investigations have shown that as the molasses left the exploded tank, it cooled due to the Boston temperatures making it more viscous (meaning it thickened up) as it went through the streets. This made rescue efforts more difficult and cleanup more difficult as well.

The tank was never rebuilt and the property became a yard for the Boston Elevated Railway (later the Massachusetts Bay Transportation Authority). Today is the site of a city owned recreational complex called Langone Park. To the east is the large Puopolo Park which has a small plaque on its entrance commemorating the disaster.

Sources

- Britannica.com-The Great Molasses Flood

- History.com-Great Boston Molasses Flood

- ForgottenNewEngland.com-The Great Boston Molasses Flood, Prohibition and Anarchists